LVT

Size: 4”x36”,5”x36”,6”x36”,7”x36”,9”x36”,12”x24”,12”x36”,16”x16”,18”x18,6”x48”,7”x48”,9”x48”,9”x60”

Thickness:2.0-5.0mm

Wear layer: 0.1-0.7mm

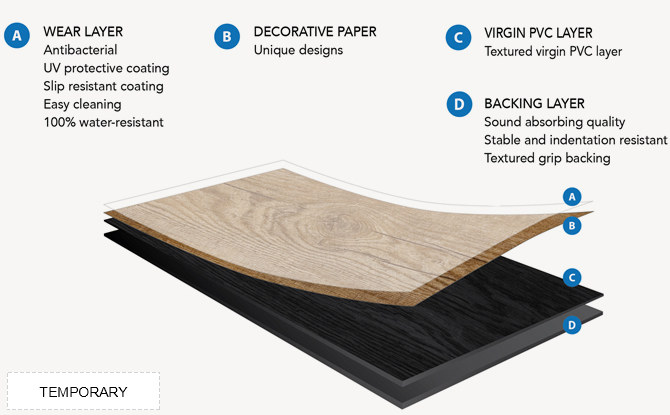

- Structure diagrams

- Technical data

- Installation instructions

- Certificate

- Test report

Technical Data (Dry back LVT)

| 1 | Dimensions | Length | ISO24342/ASTM F2055 | ± 0.50 mm | |

| Width | ± 0.20 mm | ||||

| 2 | Overall Thickness | ISO24346 /ASTM F386 | Average + 0.13 /-0.1mm | ||

| 3 | Squareness | Length | ISO24342/ASTM F2055 | ≤ 0.35 mm | |

| Width | ≤ 0.25 mm | ||||

| 4 | Dimensional Stability (6h - 80℃) | ISO23999 | ≤ 0.25 % | ||

| 5 | Curl (6h - 80℃) | ISO23999/ASTM F2199 | ± 2.0 mm | ||

| 6 | Flexibility | ISO24344/ASTM F137 | Through the 2inches diameter mandrel, the floor specimen has no crack or break. | ||

| 7 | Colour Fasteness | ISO 105 B02/ASTM F1515 | ≥ 6/Δ E≤8 | ||

| 8 | Abrasion Resistance | EN660-2 | Pass | ||

| 9 | Wear Layer Abrasion Resistance | EN 13329 (S-42, 200 cycle change) | IP≥4000cycles(0.55mm wear layer), IP≥1800cycles(0.30mm wear layer) | ||

| 10 | Castor Resistance | ISO4918 | No visible damage after 25000 revolutions | ||

| 11 | Height Difference | ISO10582/EN13329 | Average ≤ 0.10 mm, Individual values ≤ 0.15 mm | ||

| 12 | Gloss Retention | EN 16094A | Rating 1 | ||

| 13 | Micro-scratch Resistance | EN 16094B | ≥ Rating 2 | ||

| 14 | Resistance to Chemicals | ISO26987 / ASTM F925 | Class 0 / Excellent | ||

| 15 | Sound Absorbtion | DIN 52210 | ﹤4dB | ||

| 16 | Impact Insulation Class | ASTM E492 | IIC47 | ||

| 17 | Sound Transmission Class | ASTM E90 | STC50 | ||

| 18 | Burning Behaviour | EN 13501-1 | Bfl – s1 | ||

| 19 | Slip Resistance | EN 13893 | DS | ||

| 20 | Static Coefficient of Friction | ASTM D2047 | Dry: 0.37 / Wet 1 : 0.69 | ||

| 21 | Thermal Conductivity | EN 12667 | 0.1167 W/(m·K) | ||

| 22 | Thermal Resistance | EN 12667 | 0.0364 (m 2 ·K) /W | ||

| 23 | Residual Indentation | ISO24343-1 /ASTM F1914 | ≤ 0.10 mm/average less than 8 %, maximum single reading 10 % | ||

| 24 | Suitable for Underfloor Heating | Yes | |||

| 28 °C MAX | |||||

| 25 | Toxicity | EN 71 | Non Toxic | ||

| 26 | VOC Emission | AgBB/DIBt | Certified | ||

| 27 | Electrical Resistance | EN 1081 | Horizontal:>1,0x1016 OHM Vertical: 5,1 x1012 OHM | ||

| 28 | Formaldehyde emission | EN 717-1 | E1 | ||

| 29 | Antistatic Performance | EN 1815 | PVC SOLE: + 3,5 KV | ||

| 30 | Phthalate | CPSC-CH-C1001-09.3 | DBP,DEHP,BBP,DINP, DNOP, DIDP,DIBP,DnHP,DCHP≤0.1% | ||

| 31 | Heavy Metals | ASTM F963 CPSC-CH-E1002-08.3 | Total Lead (Pb) | ≤100PPm | |

| SOL. Lead (Pb) | ≤90PPm | ||||

| SOL. Mercury (Hg) | ≤60PPm | ||||

| SOL. Chromium (Cr) | ≤60PPm | ||||

| SOL. Arsenic (As) | ≤25PPm | ||||

| SOL. Antimony (Sb) | ≤60PPm | ||||

| SOL. Barium (Ba) | ≤1000PPm | ||||

| SOL. Selenium (Se) | ≤500PPm | ||||

| SOL. Cadmium (Cd) | ≤75PPm | ||||

-

12

2018-10

· Self-adhesive Vinyl Flooring Installation Instruction

2018-10-12For best results, store tile at room temperature of at least 68"F for 48 to 72 hours prior to installation. Open each carton. Don't stack the tile cartons. Installation surface should also be maintained at about 68"F. -

11

2018-10

· Dry back LVT Installation Instruction

2018-10-11LUXURY VINYL FLOORING PROGRAM GENERAL GUIDELINES All instruction and recommendations are based on the most recent information available.they should be followed for an ideal installation. 1.Dri Back Vinyl Plank and Tile should be installed in indoor climatecontrolled locations between 65°-85°F.It sho…

-

CE Certificate for LVT

-

CE Certificate

-

ISO Certificates_China

-

ISO Certificates_China

-

ISO Certificates_China

-

ISO Certificates_China

-

ISO Certificates_China

-

ISO Certificates_China

-

Greenguard Gold Certific…

-

Greenguard Gold Certific…

-

Assure for WPC

-

CE Certificate for LVT(n…